Key Takeaways

- Netting enhances warehouse safety by preventing falling objects and protecting personnel.

- Advanced netting materials and designs contribute to operational efficiency and sustainability.

- Integration of netting with innovative technologies offers real-time monitoring and improved inventory management.

Introduction

As the demands on modern warehouses evolve, so too do the tools and materials that support safe, effective operations. Among these advancements, netting has emerged as a highly versatile solution that adapts to safety, productivity, and eco-conscious challenges. Warehouses of all sizes now rely on various material handling nets to safeguard workspaces, secure inventory, and maintain streamlined workflows.

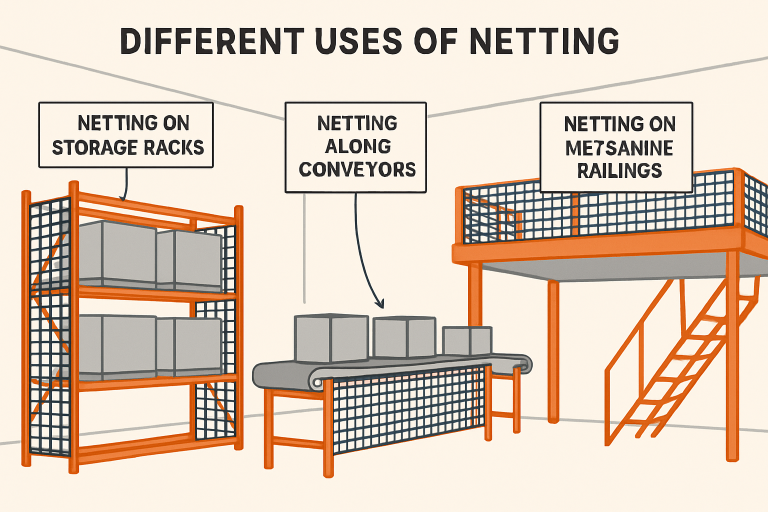

Netting technologies not only protect but also contribute to process efficiency and environmental goals. Whether used to prevent items from falling from racks, keep goods secure on conveyor systems, or provide barriers on mezzanines, these innovative applications are reshaping industry standards and supporting smarter, safer facilities.

Forward-thinking warehouse operators also utilize netting as part of broader digital initiatives, integrating smart sensors for advanced monitoring. As the market continues introducing new materials and eco-friendly designs, netting stands out for its adaptability and impact across various modern warehouse challenges.

Beyond warehouses, the effectiveness of netting is apparent in adjacent industries where stability, safety, and compliance are priorities. Construction netting offers similar protective advantages, showcasing the versatility of net-based solutions in environments where preventing debris or falls is critical.

Enhancing Safety with Pallet Rack Netting

In today’s fast-paced warehouses, minimizing risk to personnel and inventory is paramount. Pallet rack netting is vital in safety strategies by acting as a barrier against items falling from shelves into walkways or work zones below. According to the U.S. Occupational Safety and Health Administration (OSHA), falling objects consistently rank among the leading causes of warehouse injuries, emphasizing the need for robust safeguards.

Durable, easy-to-install net systems reduce both injury risk and product loss by containing errant goods where they belong. With customizable options to fit various racking configurations, netting can be seamlessly retrofitted to address unique challenges in each facility.

Improving Efficiency with Conveyor Netting Systems

Conveyor belts are essential for moving items quickly and reliably across a warehouse, but the potential for products to slip off a conveyor introduces inefficiencies and hazards. Conveyor netting systems mitigate this risk by forming a catchment barrier along the conveyor’s pathway, significantly decreasing downtime due to lost inventory or needed cleanup.

These solutions are highly customizable, with nets available in various strengths and mesh sizes to accommodate small packages, larger parcels, or heavier loads. Netting supports an uninterrupted workflow by containing goods during transit, ensuring compliance with workplace safety standards, and helping maintain product quality.

Utilizing Mezzanine and Walkway Netting for Fall Protection

Warehouses increasingly utilize vertical space with elevated mezzanines and walkways, introducing unique hazards as they expand storage capacity. Installing netting along the edges of platforms and walkways establishes an effective fall protection system. This protective barrier reduces the risk of falls from height—a significant concern in warehouse accident statistics—and helps businesses align with stringent fall protection regulations from agencies like OSHA.

In addition to physical safety, this peace of mind supports productivity and morale, as employees trust their working environments.

Advancements in Netting Materials and Design

Technological innovation has transformed netting from basic rope or polypropylene mesh into a sophisticated product for specific warehouse demands. Modern materials like High-Density Polyethylene (HDPE) offer exceptional resistance to UV exposure, chemicals, and abrasion, extending useful lifespans even in challenging settings. Fire-retardant treatments and the development of biodegradable and recycled-content nets align netting solutions with strict safety and sustainability targets.

These advancements are pushing the market towards higher standards. For example, HDPE-based netting is now widely adopted for its durability in varying climates and warehouse environments. Concurrently, warehouse operators are exploring alternatives informed by best practices in advanced manufacturing and material science.

Integration with Smart Technologies

The digital transformation of warehouses extends to netting through integration with the Internet of Things (IoT) and sensor-driven monitoring. Innovative netting solutions embed sensors to detect tears, record environmental data, or trigger alerts upon unauthorized access or material breach. Real-time feedback equips warehouse managers to address problems proactively, schedule timely maintenance, and optimize inventory management.

These state-of-the-art systems boost security and operational transparency by combining physical barriers with digital intelligence, feeding valuable data back into warehouse management systems for analysis and continuous improvement.

Supporting Sustainable Practices

Warehouses are increasingly expected to demonstrate environmental stewardship, and netting solutions are evolving in kind. The industry has introduced biodegradable nets, including edible versions made from plant-based materials, representing a significant departure from traditional, non-recyclable plastics. These alternatives support environmental certifications and responsible business practices by reducing landfill waste and resource footprints.

The adoption of sustainable netting advances companies’ eco-conscious credentials and may also yield long-term cost savings in waste disposal and regulatory compliance.

Conclusion

Netting has become a cornerstone of modern warehouse operations, touching every part of the facility—from the highest mezzanine to the fastest-moving conveyor. With enhanced materials, smart integrations, and a push toward sustainability, innovative netting applications deliver multifaceted value: securing personnel, safeguarding inventory, and supporting business goals of efficiency and environmental responsibility. As warehouse environments grow more complex, adaptable netting solutions will remain vital in ensuring that safety and progress go hand in hand.